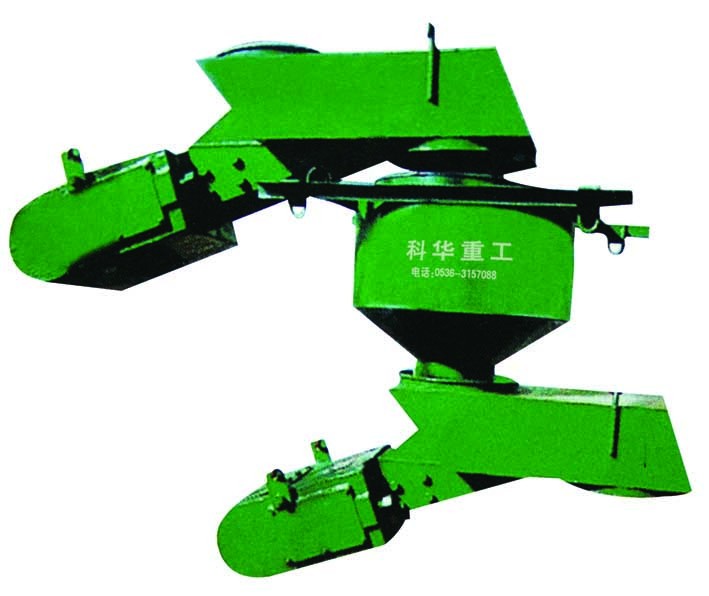

The loss-in-weight scale batching system is a continuous static measurement weighing batching equipment. Widely used in cement, glass, metallurgy, chemical, food, feed and other industries. Such as: raw material batching, clinker batching, electricity, chemical industry batching technology, glass factory batching technology, grain and oil, feed production batching technology, etc. The batching equipment is the preferred batching equipment by the National Building Materials Bureau, and its application effect is better than that of various cantilever and speed-regulating belt scales. With mill load, closed-loop control of component detection system, it has been widely used in batching measurement in cement, glass and chemical industries. Weightless scale batching system - working principle:

The feeding electric vibrating machine and the weighing hopper are softly connected, and the gravity is separated. Although the unloading electric vibrating machine is also softly connected, its gravity and the weighing hopper are supported by three tension sensors as a whole, and the material column in the weighing hopper is supported by three tension sensors. link. When working, the feeding electric vibrating machine first feeds the weighing hopper, and when the given upper limit of the given weight of the silo is reached, the feeding is stopped. After a period of time, the unloading electric vibrating machine starts to unload, and when the unloading reaches the given lower limit of weight, it stops unloading; the action is repeated. The flow measurement of the material is determined by the weight of the material lost in the silo, so it is called a loss-in-weight scale.

The system control host adopts MCS-586 (686) standard industrial control computer, with reliable performance; it can control two mills and 16-way scales for batching measurement at the same time. And there are formula calculation, automatic input of ingredients, multi-page display, automatic online reminder. And it can easily form a distributed control (DCS) with the host computer;

Weightless scale batching system - system technical indicators and functions:

1. System measurement accuracy ≤± 0.5%

2. Computer power supply: 220V+10%; 50Hz, 500M A.

3. Material ratio measurement of 1-16 points. Maximum output when single channel: 45T/h

4. Manually input the content of ingredients, and automatically calculate the proportion of ingredients.

5. Equipped with upper computer feeding control and mill load closed-loop control interface, which can realize upper computer command or automatic control of mill load.

6. Multi-element analysis automatic signal input interface can be added.

7. The data protection battery in the machine can automatically protect the clock and all data from power failure.

8. Equipped with a communication interface, it can be connected with the central control room management machine to form a network, and remote communication can also be configured according to work needs.

Weight loss scale batching system - system working conditions:

1. Ambient temperature: -10℃—+40℃

2. Power supply voltage: 220V± 10%

3. Power frequency: 50Hz±4

4. Relative humidity: <85%

Loss-in-weight scale batching system - process parameters and dimensions:

型号 | 产量t/h | 上料电振机 | 下料电振机 | 拉力传感器 | 计量仓容积 | H | H1 | H2 | H3 | H4 | H5 | H6 |

KHS-5 | 1~5 | 100W | 100W | 100Kg | 0.12m3 | 1520 | 410 | 820 | 290 | 215 | 850 | 350 |

KHS-10 | 5~10 | 200W | 100W | 200Kg | 0.23m3 | 1570 | 450 | 820 | 300 | 290 | 850 | 350 |

KHS-20 | 10~20 | 450W | 300W | 300Kg | 0.34m3 | 1855 | 635 | 820 | 400 | 300 | 850 | 350 |

KHS-30 | 20~30 | 650W | 450W | 700Kg | 0.70m3 | 2095 | 735 | 820 | 540 | 400 | 850 | 350 |

H7 | H8 | L | L1 | L2 | D | D1 | D2 | B | B1 | B2 | B3 | B4 |

420 | 30 | 1850 | 1064 | 860 | 500 | 400 | 260 | 580 | 330 | 330 | 250 | 620 |

420 | 30 | 2100 | 1300 | 900 | 700 | 400 | 260 | 780 | 330 | 330 | 250 | 620 |

420 | 30 | 2480 | 1475 | 1000 | 850 | 550 | 320 | 930 | 535 | 535 | 300 | 750 |

420 | 30 | 3040 | 1855 | 1030 | 920 | 600 | 320 | 1000 | 555 | 555 | 400 | 950 |