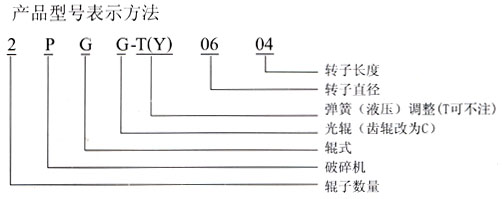

According to the number of rollers, the roller crusher can be divided into several types: single roller, double roller and multi-roller. According to the shape of the roller surface, it is divided into smooth roller and toothed roller. The smooth roller is mainly suitable for medium and fine crushing of medium hardness ores. The toothed roller is suitable for coarse and medium crushing of brittle and soft materials.

Working principle: The material to be crushed falls between the two rollers through the feeding port and is brought between the rollers by the action of frictional force for extrusion and crushing, and the finished material falls from the bottom. When encountering hard or unbreakable objects, the rollers can automatically retreat by the action of hydraulic cylinders or springs, so that the gap between the rollers increases, and the hard or unbreakable objects fall down, thus protecting the machine from damage. There is a certain gap between the two rollers rotating in opposite directions. By changing the gap, the maximum discharge size of the product can be controlled. The double-roll crusher uses a pair of oppositely rotating round rollers, while the four-roller crusher uses two pairs of oppositely rotating round rollers for crushing.

Features: The double-roller crusher adopts V-belt or universal joint coupling to drive and adjust the gap between the two rollers. The four-roll crusher adopts a V-belt drive and adjusts the gap between the rollers.

Main technical parameters of double roll crusher:

类型 | 型号 | 辊子直径/长度 mm | 最大进料粒度 mm | 出料粒度 mm | 生产能力 t/h | 电动机功率 kw | 辊子转速 rpm | 重量 kg |

双辊破碎机 | 2PG3030 | Φ300/300 | 20 | 0-15 | 1.5-5 | 2x2.2 | 60 | 543 |

2PG4025 | Φ400/250 | 32 | 0-8 | 5-10 | 2x5.5 | 200 | 1300 | |

2PG6040 | Φ600/400 | 85 | 0-12 | 4-15 | 2x11 | 120 | 3500 | |

2PG6090 | Φ600/900 | 85 | 0-12 | 8-35 | 2x15 | 120 | 8300 | |

2PG7550 | Φ750/500 | 100 | 0-12 | 10-40 | 2x15 | 80 | 9200 | |

2PG120100Y | Φ1200/1000 | 40 | 2-12 | 15-90 | 2x45 | 75 | 46400 | |

2PG120100T | Φ1200/1000 | 40 | 2-12 | 15-90 | 2x45 | 75 | 45400 |

The main technical parameters of the four-roll crusher:

型号 | 转子工作直径/长度 (mm) | 辊子间隙 (mm) | 进料粒度 ≤mm | 产量 t/h | 电动机 | 外形尺寸 | 重量 t | |

功率kw | 电压v | |||||||

4PGG-750500 | Φ750x500 | 0-12 | 85 | 20-60 | 11/24/30 | 380 | 2.76x3.59x2.65 | 19.2 |

4PGG-Y0907 | Φ900x700 | 0-12 | 100 | 30-70 | 15/24/30 | 9.0x4.2x3.2 | 27.2 | |

4PGG-T0907 | Φ900x700 | 0-12 | 100 | 30-70 | 30/15/22 | 4.2x3.2x3.2 | 26 | |

4PGG-Y1210 | Φ1200x1000 | 0-12 | 100 | 40-80 | 40/55/75 | 9.61x5.6x4.24 | 67 | |

Main technical parameters of tooth roller crusher:

型号 | 上/下齿辊直径x长度 mm | 进料粒度 mm | 出料粒度 mm | 破碎能力 t/h | 电动机功率 kw | 重量 kg | 外形尺寸 mm |

2PGC4550 | 450x500 | < 200 | < 12 | 15-30 | 18.5 | 4300 | 2492x2160x760 |

2PGC6075 | 600x750 | < 200 | < 12 | 20-50 | 30 | 6800 | 3265x2780x1360 |

2PGC60100 | 600x1000 | < 200 | < 12 | 30-70 | 45 | 8700 | 4820x2887x1360 |

2PGC9090 | 900x900 | < 300 | < 12 | 40-80 | 45 | 13200 | 3974x2827x1650 |

2PGC1012 | 1000x1200 | < 300 | < 12 | 60-120 | 55 | 13500 | 4820x2860x1450 |

4PGC40/38/60 | 400/380x600 | < 300 | < 12 < 25 | 30-60 50-80 | 18.5/22 | 7100 | 2355x1805x1450 上230r/min 下280r/min |

4PGC40/38/120 | 400/380x1200 | < 300 | < 12 < 25 | 50-90 80-150 | 75 | 9600 | 3650x1805x1450 |

4PGC76173 | 760x1730 | < 300 | < 12 < 25 | 180-300 250-400 | 3*75 | 17600 | 5770x1920x1860 |

4PGC80100 | 800x1000 | < 300 | < 12 < 25 | 60-100 90-125 | 75 | 16000 | 5270x1970x1920 |

4PGC11080(Y) | 1000/1100x800 | < 300 | < 8 < 13 < 25 | 100-140 130-180 170-260 | 55/75 | 21000 | 4614x1824x2340 (4614x3834x2340) |