A use of ZKC frame chain slag remover

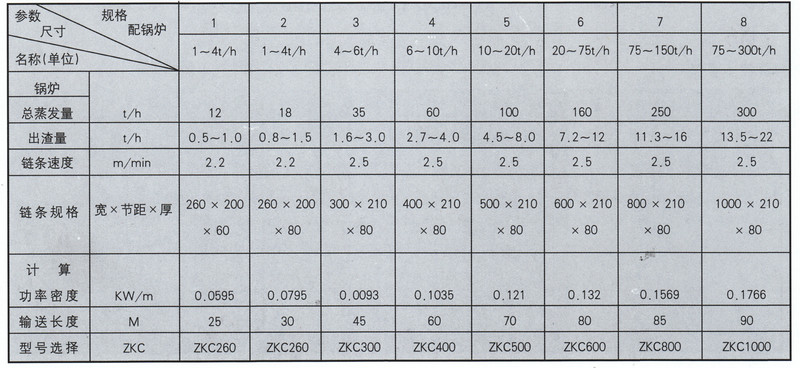

The frame chain slag remover is suitable for small thermal power plants. The continuous removal of ash and slag in boiler rooms in district central heating or similar situations is suitable for the combined use of multiple boilers for slag removal. This equipment can be used not only for wet slag removal, but also for dry circulating fluidized bed boiler with slag cooler. It is a widely used cinder conveying machine.

Second, the type of ZKC frame chain slag remover

This slag remover is divided into two types: low-level unloading and high-level unloading according to the discharge height of the head.

The motor used in the frame chain slag remover is divided into two types: fixed speed and variable speed. Among them, the variable speed motor is divided into electromagnetic speed regulation motor and frequency conversion speed regulation motor.

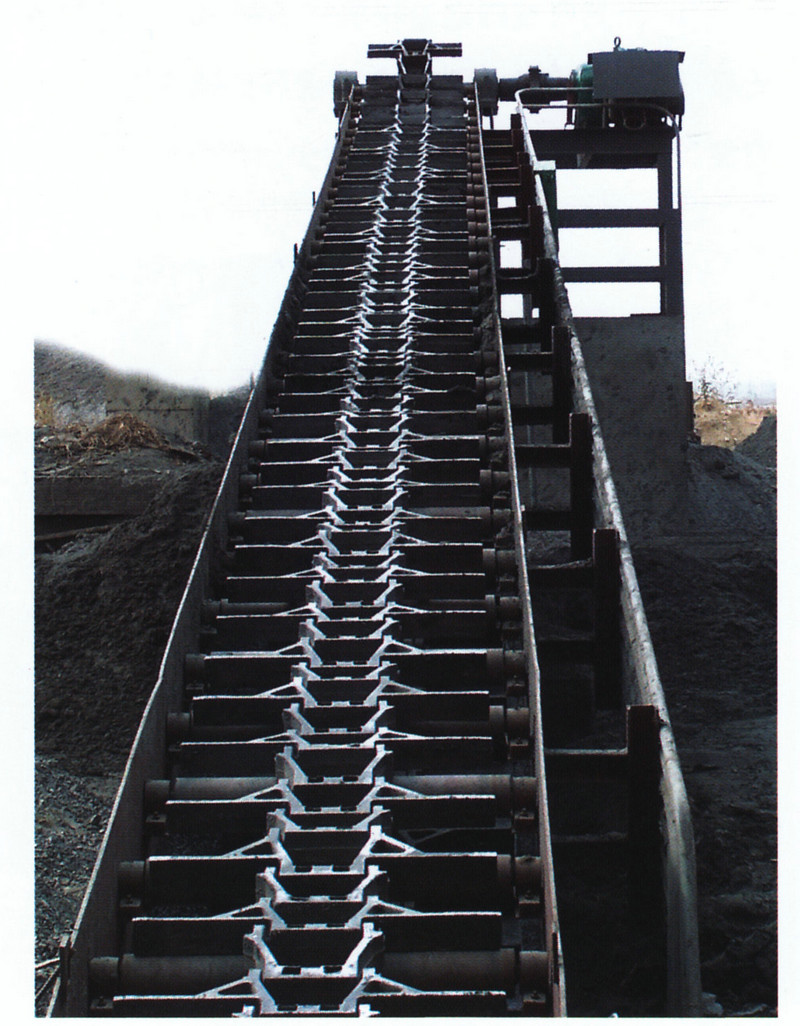

3. Structure and characteristics of ZKC frame chain slag remover

The frame chain slag remover is a continuous working slag conveying equipment, which is composed of a driving mechanism, a driving mechanism, a tail wheel steering mechanism, a slag groove, a chain and an idler.

The drive mechanism of this slag remover is composed of a motor, a cycloidal pinwheel reducer, a driving sprocket and a tensioning slide. The driving mechanism is a backpack type. The whole machine has good force and is easy to install and adjust. The drag sprocket tooth plate is a detachable mechanism for easy replacement. There are two types of chain links: base chain and wing chain. The ZKC-260 frame chain slag remover has only the base chain, and the ZKC-350 frame chain slag remover and the above specifications are composed of two base chains and one winged chain link.

The bottom of the slag remover tank is lined with wear-resistant and corrosion-resistant basalt cast slate, which can greatly improve the service life of the casing and reduce the wear of the frame chain.

ABOUTShandong Kehua Heavy Industry Technology Co., Ltd., formerly known as Linqu County Kehua Automatic Control Equipment Factory, was founded in April 1993. On January 10, 2007, the company changed its name to Weifang Kehua Automatic Control Equipment Co. Ltd

ABOUTShandong Kehua Heavy Industry Technology Co., Ltd., formerly known as Linqu County Kehua Automatic Control Equipment Factory, was founded in April 1993. On January 10, 2007, the company changed its name to Weifang Kehua Automatic Control Equipment Co. Ltd PRODUCTThe company's main products are: electronic belt scales, spiral scales, loss-in-weight scales, quantitative feeders, batching systems, hoists and other heavy machinery and equipment. Products are widely used in chemical, cement, steel, mining, thermoelect

PRODUCTThe company's main products are: electronic belt scales, spiral scales, loss-in-weight scales, quantitative feeders, batching systems, hoists and other heavy machinery and equipment. Products are widely used in chemical, cement, steel, mining, thermoelect CONTACTIt is the eternal pursuit of the company to create famous brand products, establish a first-class enterprise, and lead the mainstream of the industry.

CONTACTIt is the eternal pursuit of the company to create famous brand products, establish a first-class enterprise, and lead the mainstream of the industry. NEWSThe company adheres to the operating principles of leading technology and winning by quality, and has close cooperative relations with many colleges and universities and scientific research institutions.

NEWSThe company adheres to the operating principles of leading technology and winning by quality, and has close cooperative relations with many colleges and universities and scientific research institutions.