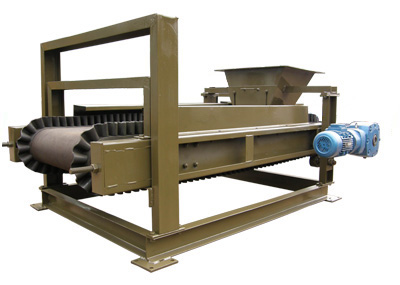

TDG speed control quantitative feeding belt scale series is based on digestion, absorption and introduction of SCHENCK, combined with long-term practice and experience, and continuously improves and optimizes the design of products. It is suitable for continuous dynamic metering and quantitative feeding of granular, block and powder materials.

TDG speed control quantitative feeding belt scale - overview:

TDG speed-adjustable quantitative feeding belt scale series adopts dynamic feeding measurement method and computer frequency conversion control, automatic belt tensioning device, deviation alarm protection and on-site control switch, which has the advantages of stable operation, high reliability, high measurement accuracy, It can work normally in harsh environments, and is suitable for batching and metering of bulk materials in building materials, metallurgy, chemical industry, grain and other industries. It is an ideal metering device for automatic control and stable product quality.

TDG speed control quantitative feeding belt scale - structural features:

1. The scale body frame is composed of cold-formed C-shaped steel plates, with novel structure and high strength, which is suitable for the design of non-standard scale bodies of various specifications;

2. Integrated direct-coupled geared motor, manufactured with imported technology, with low noise, low vibration, dust resistance, long life and high reliability;

Geared motor with anti-torque support plate, shaft-mounted structure. It is directly connected with the active drum of the scale body, which is extremely convenient for installation, debugging and maintenance.

3. The endless belt without joints can be selected according to the process: flat belt, baffle structure, skirt belt structure;

4. The design of the weak magnetic gear speed measuring device, cooperates with the speed measuring circuit to truly reflect the motor speed, and the speed measuring signal is accurate and reliable;

5. The scale body feeding device comes with a pallet, which can control the feeding amount and sealing material, so that the scale body can be calibrated and zeroed;

TDG speed control quantitative feeding belt scale - main technical parameters:

System accuracy: ≤±0.5%;

Speed range: 1:10;

Speed regulation mode: frequency conversion speed regulation;

How it works: Continuous

Use environment: instrument -50~50℃; scale body -30~50℃; relative time degree ≤90%

Power supply: ~220V -15%-10%, 50Hz (microcomputer part);

Feeding range: 0.2~2000t/h. Process flow simulation diagram:

Speed signal; 40 pulses/rev