Overview

The rotor powder feeding system is a continuous metering equipment for powder feeding developed on the basis of digesting and absorbing foreign advanced powder feeding technology.

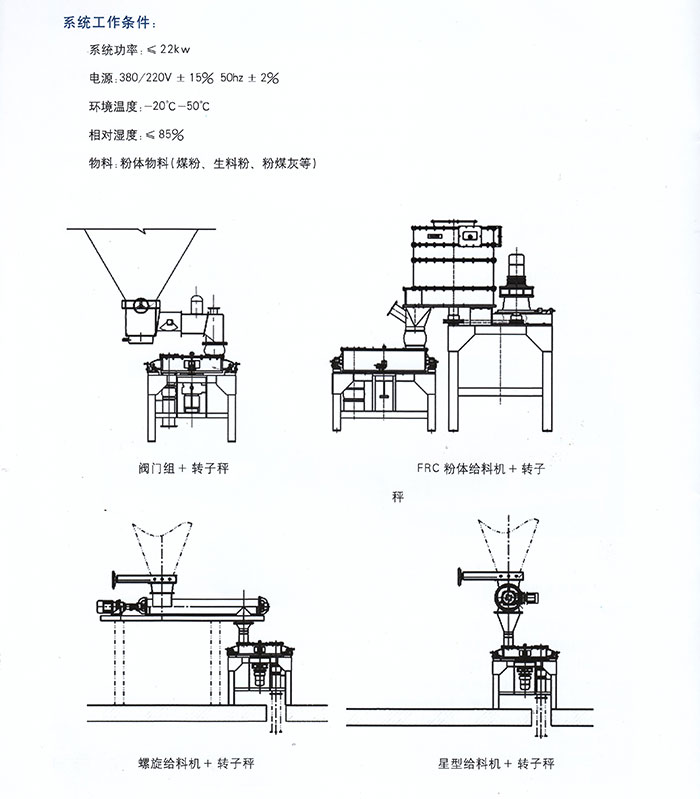

The rotor powder feeding system consists of:

Spiral gate valve

Pre-feeder (FRC powder feeder, star feeder, screw feeder, valve group)

Rotor scale

soft connection

control system, etc.

Rotor scale structure and principle:

The rotor scale uses a balance structure to weigh the material. The balance body composed of a motor, an impeller rotor and a disc has a soft connection at the inlet and outlet, which does not affect the force rotation of the balance body, and ensures the balance on both sides of the balance body during design and manufacture. During the powder supply process, due to the rotation of the impeller, the material flows evenly in the semi-circle from the feed port to the discharge port, and the load sensor can accurately sense the weight of the powder on the semi-circle. The weight signal and the impeller speed signal are in the microcomputer The flow signal is obtained after the calculation is carried out inside, and the control amount is transmitted to the variable frequency speed regulating motor (including the pre-feeder variable frequency speed regulating motor) after comparing with the set value, and the powder can be adjusted by adjusting the speed of the rotor scale and the pre-feeder. flow.

Features:

The powder feeding system adopts a multi-layer sealing structure to ensure continuous powder conveying, uniform and stable feeding, no arching, jet flow, blockage, etc.

High material accuracy.

Due to the use of a flexible seal, the problems caused by jet flow, wear and temperature changes are solved.

The rotor scale adopts a balance structure, the balance body is balanced on both sides, and the sensor only detects the weight of the fine body.

The inlet and outlet and the fulcrum are on the same axis, and the impact of the material does not affect the balance of the balance.

Good controlled performance, wide flow adjustment range and high measurement accuracy.

The structure is simple, compact, fully sealed, easy to install and maintain.

Adopt Plc+hmi control system, powerful function

Measurement error: ≤±0.5%

Control accuracy: ≤±o.i%

Feeding capacity: 3~1 00『T13/h

Production capacity:

| 型号 | 生产能力( F113/h) |

| FZC-1 | 1 0 |

| FZC-2 | 30 |

| FZC-3 | 60 |

| FZC-4 | 1 00 |