External structure

1. The edge height of the chain plate machine board is generally 80-120mm, depending on the conveying material and the conveying volume can be appropriately changed in the design, the material is continuously stored on the chain plate, in order to prevent excessive material leakage, the inclination angle is generally Not more than 15°, its external structure is shown in the figure below.

2. The material of the chain bucket machine is stored in a single chain bucket for transportation. During the conveying process, depending on the action of gravity and rollers, the chain bucket is always in a horizontal state, so it can be used for conveying materials at a large inclination angle. The inclination angle can reach 45°, and the common external structure is shown in the figure below.

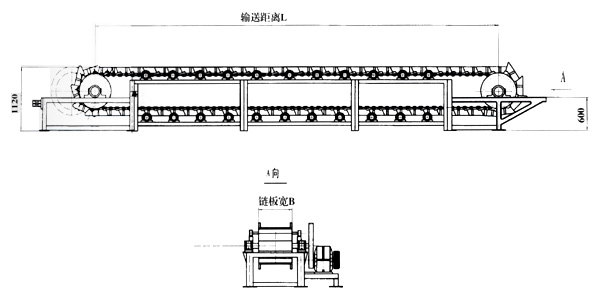

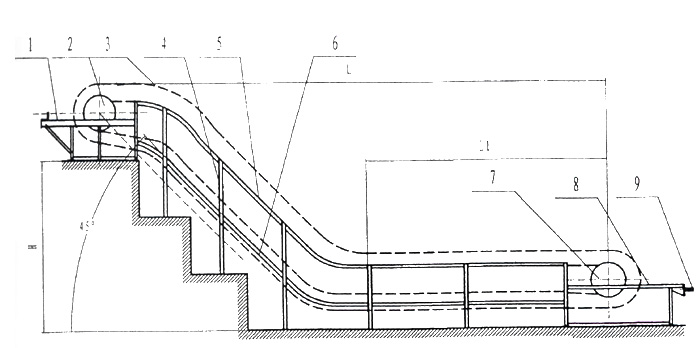

Schematic diagram of the structure of HB chain plate conveyor

1. Head 2. Power drive sprocket 3. Carrying assembly 4. Inclined middle branch 5. Upper rail 6. Lower rail 7. Tail sprocket 8. Tailstock 9. Lead screw tensioning device

Precautions

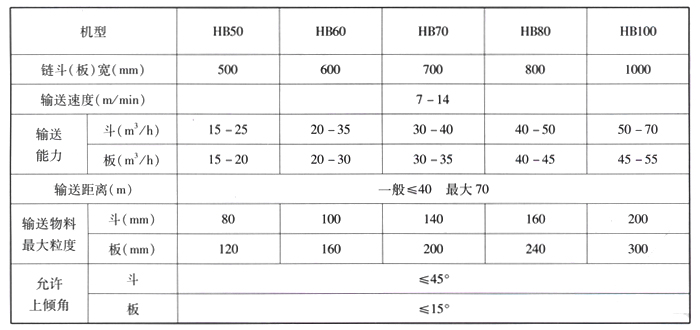

1. The chain bucket machine and the chain plate machine are mainly used to convey materials with strong wear and high temperature. When ordering, the user should specify the model, the center distance between the two wheels, the inclination angle, the maximum conveying capacity and other process parameters.

2. The power device installed in the head, left and right of the chain bucket (plate) can be changed according to user requirements.

3. The conveying speed should be 8~10m/min, too low will affect the conveying volume, too high noise will increase the wear and tear. And HB800 and HB1000 are suitable for conveying materials with small bulk density.