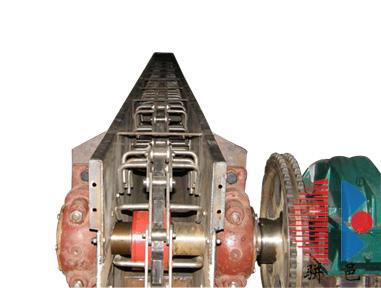

1. Working principle

There is internal friction and internal pressure between the particles of the bulk material. When the conveyor chain and its accessories of the conveyor move, the bulk material is pulled in the same direction of the conveyor chain in the groove of the conveyor, so that the particles of the bulk material are pulled in the same direction. The internal pressure increases, so that the friction force between the bulk materials increases. When the internal friction force is greater than the friction force between the bulk material and the side wall of the machine groove, the bulk material will move forward along the moving direction of the conveyor chain, and the increased internal pressure ensures the stable state between the bulk material layers, thereby It forms a continuous flow of the whole, just like the flow of water. (When the ratio of the height of the material layer to the height of the machine groove meets certain conditions, the material flow is stable, and the material speed is approximately equal to the chain speed.)

2. Typical transportable materials

FU chain conveyor can transport more than 1,000 kinds of powder, granular and small block materials, the typical ones are:

Cement finished products, cement raw meal, yellow sand, limestone powder, coal powder, coke powder, fly ash, sawdust, crushed ice, stone powder, urea, synthetic fertilizer, soap powder, soda powder, soda ash, plastic particles, polyethylene, resin, Potassium sulfate, ammonium sulfide, clay powder, quartz sand, iron ore powder, crushed slag, salt, starch, wheat, cottonseed, crushed feed, maltose, rice, corn, soybean, etc.

Main feature

Large conveying capacity: Compared with other types of conveyors, the FU chain conveyor has the advantages of small size and large conveying capacity. It only needs 1/5 of the space of the belt conveyor or 2/3 of the space of the screw conveyor. Convey the same flow of material. The conveying capacity is 6m3/h~500m3/h.

Long service life and low cost of use: The normal life of the conveyor chain made of alloy steel through scientific heat treatment is more than 5 years, and the life of the rollers on the chain is not less than 1 year (the most vulnerable part of the whole machine), so as to guarantee the annual life of the conveyor chain. The maintenance amount is less than one time, which greatly reduces the use cost and improves the production efficiency.

Low energy consumption: With the help of the internal friction of the material, most of the work done by the moving parts is converted into effective work. The use of chain hook conveying greatly reduces the resistance of the material to it, so that the energy consumption is only 30% to 60% of the screw conveyor.

Sealed and safe: The whole machine is completely sealed, so that the dust can be drilled seamlessly, and the operation is convenient, safe and reliable.

Flexible process layout: Allows you to choose various types of inlet and outlet ports at any position of the casing, which can be arranged on elevated, ground or pit, and can be installed horizontally or on a slope (≤15°).

Complete series: FU series include FU150, FU200, FU270, FU350, FU410, FU500, FU600, FU700.

4. Technical parameters

Table 1: Technical parameters of various types of chain conveyors

| 型号 | 槽宽 (mm) | 理想 粒度 (mm) | 10%最大粒度(mm) | 基本输送量(m3/h) | 物料湿度(理论) |

| 链速 |

| 11 | 13.5 | 17 | 21 | 22.7 | 28 |

| FU150 | 150 | <4 | <8 | 10 | | 16 | | 20 | |

| FU200 | 200 | <5 | <10 | 20 | | 30 | | 40 | | ≤5%手抓捍成团撒手后仍能松散为度 |

| FU270 | 270 | <7 | <15 | 35 | 45 | 55 | | 70 | 80 |

| FU350 | 350 | <9 | <18 | | 70 | 85 | 100 | | 130 |

| FU410 | 410 | <11 | <21 | | 90 | 110 | 138 | | 175 |

| FU500 | 500 | <13 | <25 | | | 170 | | 210 | 270 |

| FU600 | 600 | <15 | <30 | | 184 | 224 | | 276 | 340 |

| FU700 | 700 | <18 | <32 | | 250 | 305 | | 376 | 460 |

The basic conveying volume is formulated with cement and other materials as the material, and the actual conveying volume can be controlled within the range of 0-20% smaller than the recommended value in this table. When using other industries to transport materials with low abrasiveness and temperature <60℃, the chain speed can also be accelerated (the fastest chain speed can reach 40m/min, see Table 2). For details, please contact the technical department of the company.

Table 2: Recommended chain speeds for conveying different abrasive materials

| 物料磨琢性 | 特大 | 大 | 中 | 小 |

| 链速m/min | 推荐 | 10 | 15 | 20 | 30 |

| 最大 | 15 | 20 | 30 | 40 |

Table 3: Optimum chain speed for conveying raw and cooked cement raw materials and finished powder| 物料 | 生料细粉或水泥成品 | 熟料细粉或水泥成品 | 生料或熟料粗粉回料 |

| 料温 | <60℃ | 60~120℃ | <60℃ | 60~120℃ |

| 最适链速(m/min) | 15~20 | 10~15 | 10~13.5 | 10~12 |

| 最大链速(m/min) | 25 | 17 | 15 | 14 |

Table 4: Discount Factor η Values for Inclined Conveying | 倾角(度) | 0~2.5 | 2.5~5 | 5~7.5 | 7.5~10 | 10~12.5 | 12.5~15 |

| η | 1 | 0.95 | 0.9 | 0.85 | 0.8 | 0.7 |

Note: When the chain conveyor tilts and rotates, the conveying capacity will decrease. At this time, the actual conveying capacity is the value in Table 1 multiplied by the discount coefficient η value.